- 2024.11.18 Mon

Advancing Fiber Optic Technology: Manufacturing Fluoride Glass ZBLAN in Space to Enhance Performance

The future of space innovation is on the brink of transforming life on Earth. In early 2024, a groundbreaking demonstration took place in space, where much higher-performance optical fiber than ever was successfully manufactured in orbit. The team managed to produce over 5 kilometers of fiber in just two weeks. In this article, we explore the story of a U.S. startup leading this frontier of space manufacturing.

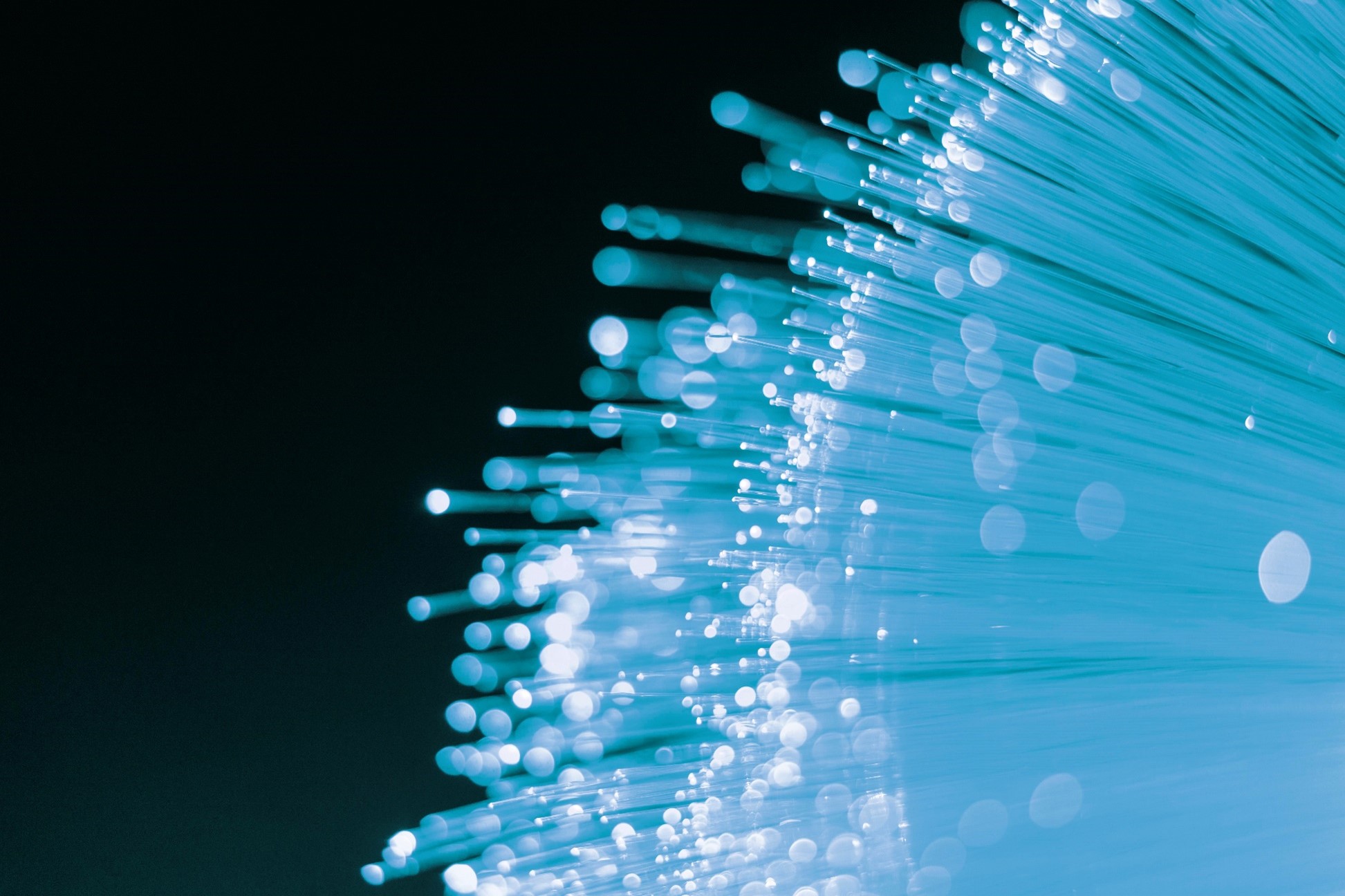

Fluoride glass is a material that offers higher transmission efficiency than regular glass, making it ideal for guiding light. While traditional glass is made from silica, the performance of silica-based glass is limited by its raw material properties. Fluoride glass, on the other hand, is made from fluoride compounds, such as aluminum fluoride. Among these, ZBLAN (Zirconium-based Fluoride Glass) stands out for its excellent strength and optical transmission properties, making it widely used for optical fibers and in ground-based lasers and amplifiers.

ZBLAN fibers are theoretically up to 100 times more efficient than conventional silica-based fibers. However, when produced on Earth, the process is hindered by thermal and density convection caused by gravity, which introduces light-scattering defects that limit the material’s potential. In early 2024, the company announced that it had successfully manufactured over 5 kilometers of ZBLAN optical Space Station

The startup at the forefront of tackling this issue is "Flawless Photonics", based in Silicon Valley, U.S. In early 2024, the company announced that it had successfully manufactured over 5 kilometers of ZBLAN optical fiber aboard the International Space Station (ISS) within just two weeks. While other companies have attempted space-based ZBLAN production before, none have achieved such remarkable results. According to Flawless Photonics, the performance of the fiber produced in space cannot be replicated on Earth due to the unique microgravity environment that enabled its creation. The 5 kilometers of fiber produced is enough to serve as a commercially viable batch, marking a significant step toward realizing space-based manufacturing for Earth-bound markets.

The experiment to manufacture ZBLAN was conducted in November 2023 aboard the ISS. With funding from the European Space Agency and the Luxembourg Space Agency, Flawless Photonics developed a specialized manufacturing platform for space use. They also received support from the U.S. ISS National Lab to launch the platform to the ISS and carried out the demonstration.

On Earth, glass production can be affected by gravity, leading to the formation of tiny bubbles in the glass or contamination from the container material during cooling, which impairs its optical properties. However, in the microgravity environment of the ISS, these issues are eliminated, enabling the creation of flawless, high-performance materials.

The optical fiber produced in space showed superior transmission efficiency and strength compared to terrestrial fiber. The fiber has been returned to Earth in April 2024 for further analysis and commercialization.

Fiber optics are widely used in communication systems, medical devices, and many other industries. As ZBLAN fibers replace traditional silica fibers, they could revolutionize various aspects of modern life.

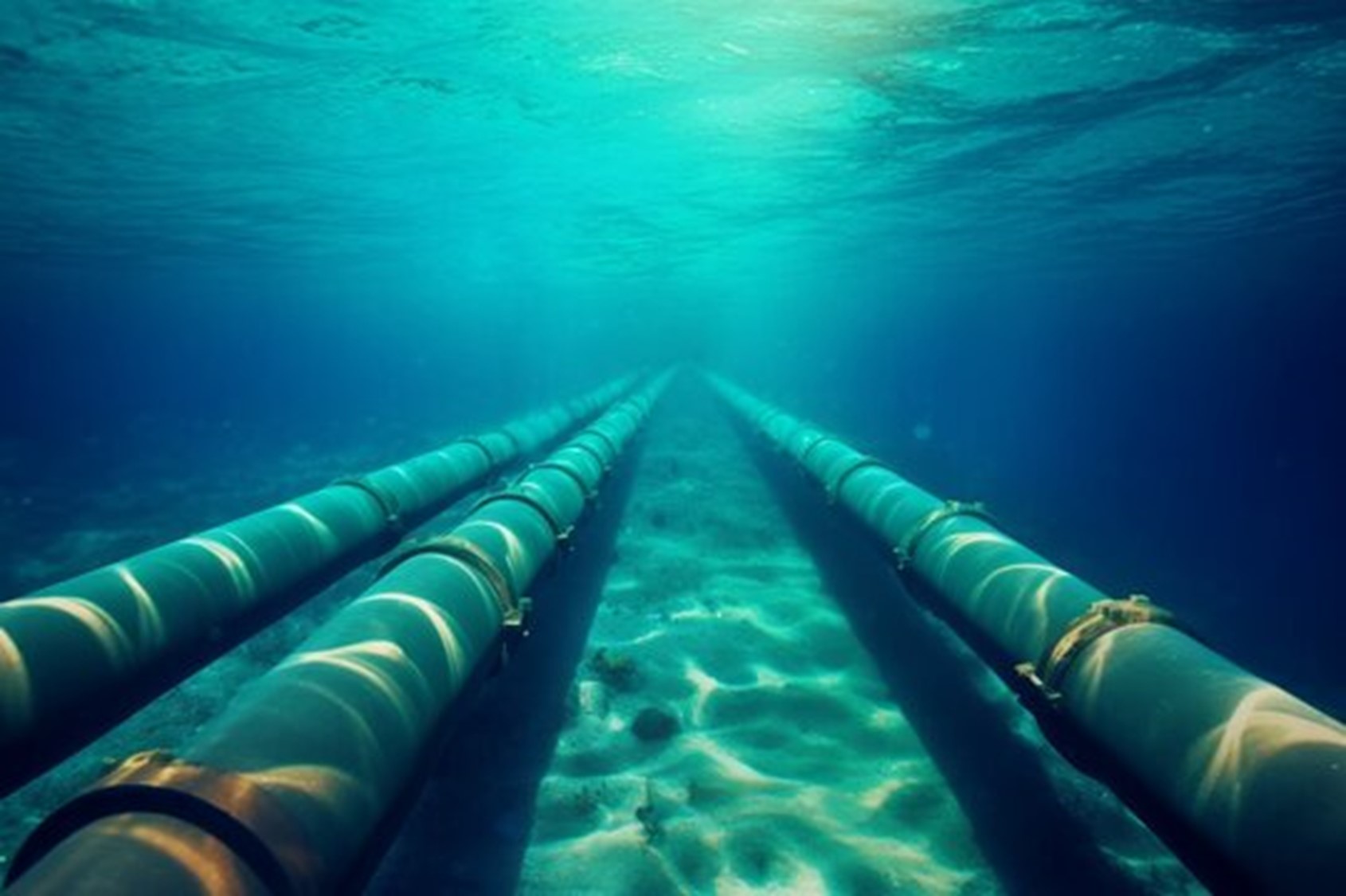

One of the ambitious "moonshot" goals of Flawless Photonics is to replace the optical fibers in undersea cables with ZBLAN. This project aims to contribute to global energy efficiency. Currently, undersea cables use silica-based fiber optics, but by switching to ZBLAN, the transmission efficiency could increase by 10 to 100 times, reducing the need for amplifiers and saving significant amounts of energy. Interestingly, the energy used by amplifiers in undersea cables accounts for approximately 1–1.5% of the world’s total energy consumption.

These advancements in fiber optic technology have the potential to address global energy challenges and lead to massive environmental benefits.

As recent applied use, fiber optics are essential in medical lasers used in cancer surgery, early diagnosis, glaucoma treatment, dental procedures, and more. The improvements in ZBLAN fiber technology are expected to have a direct impact on the medical field, further enhancing its applications.

Space-made materials and products are on the leading edge of transforming life on Earth. The advancements being made in space manufacturing are not just about creating new materials but are part of a larger vision of how space exploration can enhance our everyday lives.

Source:

- Flawless Photonics

- ISS National Lab: Flawless Photonics - Fiber Optics in Space

- SpaceNews: Flawless Photonics - Kicking Glass

- NASA: New Window Improves Science Views from the ISS